LESER IN THE UNITED KINGDOM

Cryogenic & Liquefied Gas

Repeatable bubble-tight sealing performance

We are Seetru in India

Why are safety valves important for cryogenic and liquefied gas applications?

Cryogenic and liquefied gases are typically stored at high pressures and low temperatures. This makes them particularly susceptible to overpressure events, which can be caused by a variety of factors, such as equipment failure, operator error, or external events such as fires or explosions.

If an overpressure event occurs in a cryogenic or liquefied gas system, the resulting pressure release can be catastrophic. Safety valves help to prevent this by automatically opening to release excess pressure, protecting the system and personnel from harm.

Quick Links:

Safety Relief Valves | Change-Over Valves

The Seetru range of safety valves for cryogenic & liquefied gas applications is built using Seetru sealing technology,

suitable for temperatures down to -196°C, and pressures up to 1100 bar. Available with PTFE, PPS, or metal-to-metal sealing.

Safety Valves suitable for the following industries/applications:

-

Pressure vessels/receivers, pressure equipment, and piping

-

Cryogenics including oxygen and special gases

-

Medical gas equipment

-

Cryogenic compressor applications

-

Container lorries, cryogenic trailers, LPG/LNG terminals, carriers, etc.

-

Industrial freezing

-

Liquefied gas storage

-

Fire fighting equipment

Enclosed Safety Relief Valves for Cryogenic & Liquefied Gas

-

Design: Enclosed Discharge

-

Materials: Bronze or Stainless Steel

-

Inlet Connections: 3/8” to 3/4”

-

Pressure Range: 0.83 to 30.76 bar

-

Design: Enclosed Discharge

-

Materials: Bronze or Stainless Steel body

-

Inlet Connections: 3/8” to 3/4” Threaded

-

Pressure Range: 53.0 to 370.0 bar

-

Design: Enclosed Discharge

-

Materials: Brass inlet with either Bronze or Stainless Steel body. Metal to metal sealing

-

Inlet Connection: 1/2” to 2” threaded connections (depending on valve bore size)

-

Pressure Range: 0.3 to 28.0 bar (depending on valve bore size)

-

Design: Enclosed Discharge

-

Materials: Stainless Steel

-

Inlet Connection: 1/2” to 2” threaded connections (depending on valve bore size)

-

Pressure Range: 0.3 to 28.0 bar (depending on valve bore size)

-

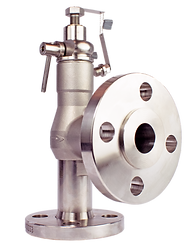

Design: Enclosed Discharge

-

Materials: Stainless Steel

-

Inlet Connections: DN15 (1/2), DN20 (3/4”) or DN25 (1”) flange – DIN EN1092 and ANSI flanges are available

-

Pressure Range: 0.3 to 28.0 bar

-

Design: Enclosed Discharge

-

Materials: Stainless Steel

-

Inlet Connections: DN25 (1”)

-

Pressure Range: 0.3 to 28.0 bar

-

Design: Enclosed Discharge

-

Materials: Stainless Steel

-

½” NPT, BSP & BSPT | 9/16” Cone & Thread | 3/4” Cone & Thread

-

Pressure Range: 35.0 to 515 bar (9*605) / 35.0 to 1100 bar (9*6H5) *Maximum set pressure for steam is 85 bar

Find more valves for Cryogenic & Liquefied Gas...

Change-Over Valves

Change-Over Valves for Cryogenic & Liquefied Gas

-

Materials of Construction: Stainless Steel

-

Seal Material: P.T.F.E

-

Maximum Safety Valve Set Pressure: 75.0 bar

-

Temperature Range: -196°C to 200°C

-

Materials of Construction: Stainless Steel with Mild Steel or Stainless Steel Internals

-

Seal Material: Elastomer / P.T.F.E

-

Maximum Safety valve Set Pressure: 65.0 bar

-

Temperature Range: -30°C to 200°C (subject to seal material)

-

System Connections: 1” to 1-1/2” BSP, BSPT, NPT, CL150 to CL600 & PN16 to PN100

-

Valve Connections: ¾” to 1” BSP, BSPT, NPT (with or without orientators), CL150 to CL600 & PN16 to PN100

-

Maximum Safety Valve Set Pressure: 100.0 bar

-

Temperature Range : -196°C to 200°C

.png)

.png)